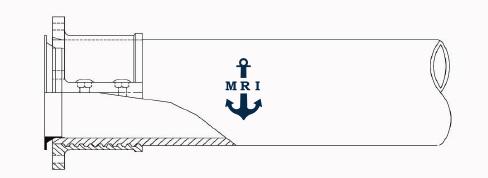

Slurry Rubber Hoses for Iron/Ore/Pellets/Mud And Sand Slurry Applications

‘M.R.I’ Brand Rubber Flexible Iron Ore Slurry Hose is an exceptionally abrasion‐resistant slurry hose. Built with best quality rubber it is recognized for its dependable performance and long wear life. ‘M.R.I’ Brand Rubber Flexible Iron Ore Slurry Hose combines outstanding abrasion resistance of a Uniform wear tube with lightweight reusable aluminum flanged couplings. This unique combination allows fast and easy on‐site assembly minimizing downtime and maintenance costs.

- Hose Body is corrugated and has wire to provide superior sealing and gripping qualities with the couplings.

- The inner wear tube is dimensionally stable, eliminating thin spots and premature failures.

- Safety factor 3.2 times the working pressure. Simple installation, no special tools needed.

- Flexible design absorbs vibration and aids in bend transitions.

DETAILS OF IRON ORE SLURRY HOSE

| Sizes from: | 2”(id) to 40”(id). |

| Standard length : | 20 mtrs , from Size : 2”(id) to 6”(id) |

| 10 mtrs , from Size : | 8”(id) to 20”(id) |

| Standard Maximum Working Pressure : | 7 kg/cm2g, 15 kg/cm2g, 20 kg/cm2g |

| Maximum Vacumn : | 90% Vacuum from Size : 2”(id) to 10”(id) 50% Vacuum from Size : 12”(id) to 20”(id) |

Slurry Hoses are also available without steel wire for gravity and discharge service only.

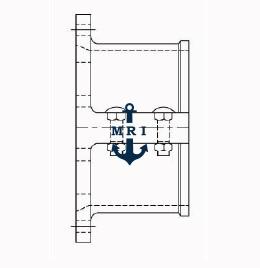

Aluminium spilt flange coupling

mply rotated around the hose until it is aligned with the connecting flange. There is no need to rotate the hose itself. The Coupling is designed for fast, simple fitting. Neither special tools or skilled personnel are needed. Each coupling is delivered with bolts for the side flanges, square headed to prevent them from turning.

The Spilt Flange Coupling is designed for use with Iron Ore Slurry Hoses and Bends. The couplings does not come in contact with the material flowing through the hose, and is thus not exposed to wear. It is manufactured from high strength aluminium alloy.

The coupling does not have to fit any specific pattern on the hose cover. It is simple fitting.

Neither special tools or skilled personnel are needed. Each

coupling is delivered with bolts for the side flanges, square

headed to prevent them from turning.

No other bolts are provided.